PaxPowerGlove_en

日本語ページはこちら。

I want to touch objects in virtual space.

So I set motion sensor in PAX Power Glove, a legendary NES controller, to control the movement of my hand in the virtual space of Unity .

The original Power Glove generate ultrasonic waves from the two ultrasonic transducers at different times to realize the motion capture.

That idea was great. But it lacked accuracy. So I decided to use motion sensor.

I used only flex sensor, out of original components.

So I set motion sensor in PAX Power Glove, a legendary NES controller, to control the movement of my hand in the virtual space of Unity .

I made that with following procedure.

- getting value of bending of fingers.

- detecting the movement of my hand with motion sensor.

- Integrating 1 and 2.

- communication by XBee.

- Integrating 3 and 4.

- realizing haptics with vibration motor.

- Integrating 5 and 6.

Materials

Hardware

| Item |

|---|

| Arduino |

| PowerGlove |

| Resistance (100k ohm * 4) |

| MPU-9150 |

Sfotware

|Item| |---|---| |Arduino IDE| |Unity| |I2C Device Library| |C# script for Unity3d|

Step 1: detecting the movement of my hand with motion sensor.

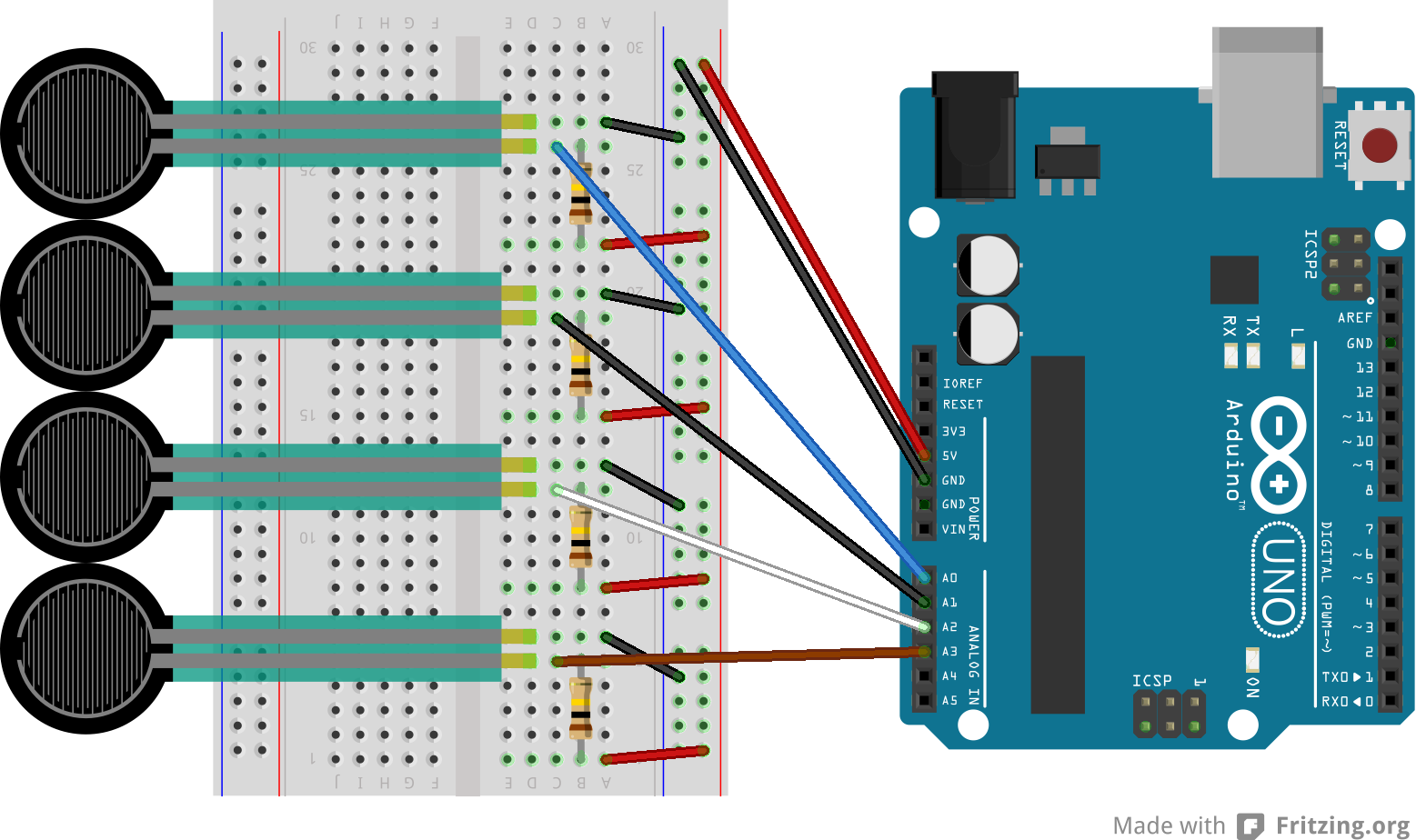

Hardware

- Remove solder. Take off wires from board.

- Connect red wires to GND. .1 Connect Other wires to resistance to Arduino's 5V. Connect Analog input between wire and resistance.

| finger | wire | analog input |

|---|---|---|

| thumb | blue | A0 |

| index finger | black | A1 |

| middle finger | white | A2 |

| ring finger | brown | A3 |

| littte finger | no wire | - |

曲げセンサは出力が抵抗値なので、同程度の抵抗器を使うことで抵抗値→電圧値に変換してArduinoに入力する、という回路が上記です。

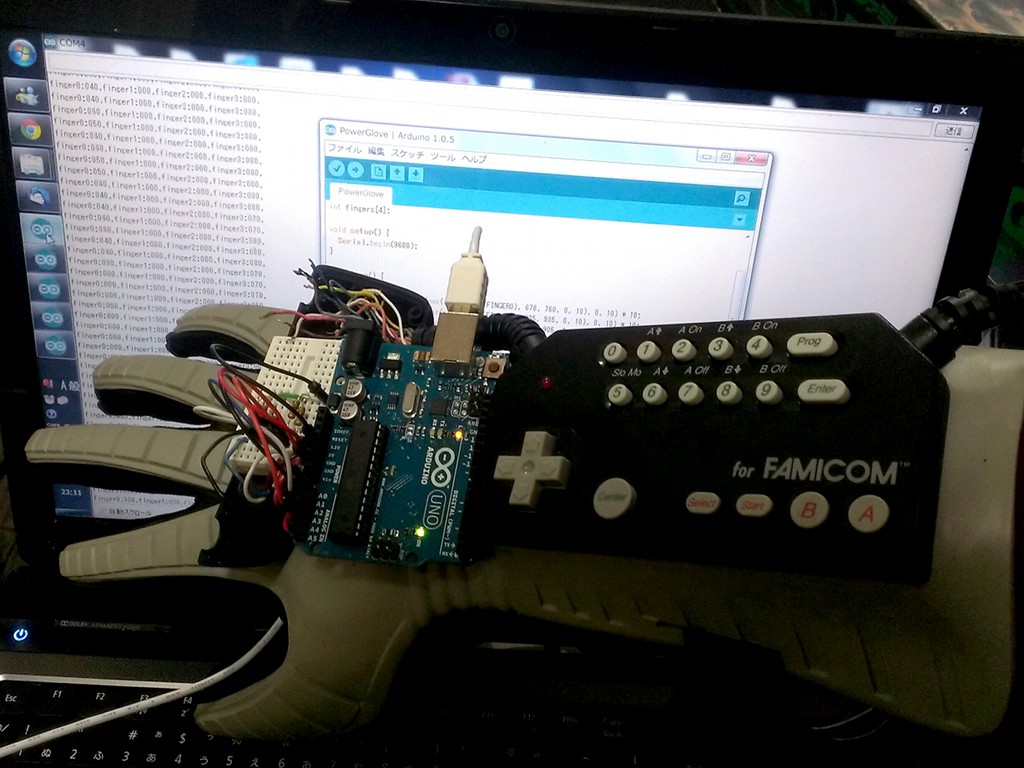

Software

- Write following sketch to Arduino.

Arduino sketch

int fingers[4];

void setup() {

Serial.begin(9600);

}

void loop() {

int i;

fingers[0] = constrain(map(analogRead(A0), 678, 760, 0, 10), 0, 10) * 10;

fingers[1] = constrain(map(analogRead(A1), 835, 935, 0, 10), 0, 10) * 10;

fingers[2] = constrain(map(analogRead(A2), 770, 905, 0, 10), 0, 10) * 10;

fingers[3] = constrain(map(analogRead(A3), 750, 910, 0, 10), 0, 10) * 10;

for (i = 0; i < 4; i++) {

Serial.print("finger");

Serial.print(i);

Serial.print(":");

Serial.print(fingers[i]);

Serial.print("\t");

}

Serial.println();

delay(200);

}

NOTE: resistance may be different with your PowerGlove.

Step 2: detecting the movement of my hand with motion sensor.

for details, see モーションセンサ . (written in Japanese)

Step 3: Integrating 1 and 2.

Hardware

- Integrate circuit of 1 and 2.

Software(1):Arduino sketch

- Modify sketch, which you made at モーションセンサ .

- Modify line 286-297.

#ifdef OUTPUT_READABLE_QUATERNION

// display quaternion values in easy matrix form: w x y z

mpu.dmpGetQuaternion(&q, fifoBuffer);

Serial.print("quat\t");

Serial.print(q.w);

Serial.print("\t");

Serial.print(q.x);

Serial.print("\t");

Serial.print(q.y);

Serial.print("\t");

- Serial.println(q.z);

+ Serial.print(q.z);

+ Serial.print("\t");

+ Serial.print(constrain(map(analogRead(A0), 678, 760, 0, 10), 0, 10) * 6);

+ Serial.print("\t");

+ Serial.print(constrain(map(analogRead(A1), 835, 935, 0, 10), 0, 10) * 6);

+ Serial.print("\t");

+ Serial.print(constrain(map(analogRead(A2), 770, 905, 0, 10), 0, 10) * 6);

+ Serial.print("\t");

+ Serial.println(constrain(map(analogRead(A3), 750, 910, 0, 10), 0, 10) * 6);

#endif

ソフトウェアの準備(2):Unityプロジェクト

- Download following zip, and open PaxPowerGlove.unity.

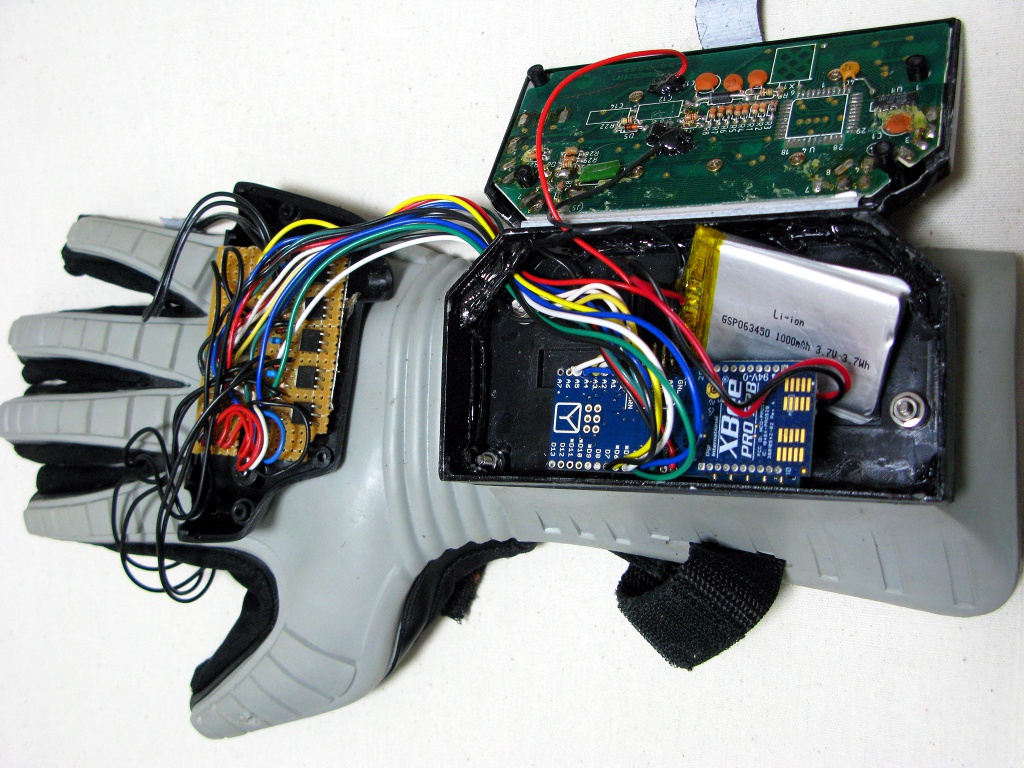

Step 4: communication by XBee.

for details, see XBee . (written in Japanese)

Step 5: Integrating 3 and 4.

さあついに、上記3と4を統合します。

- Modify Arduino sketch.

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

- TWBR = 24; // 400kHz I2C clock (200kHz if CPU is 8MHz)

+ TWBR = 12; // for Arduino Fio

// initialize serial communication

// (115200 chosen because it is required for Teapot Demo output, but it's

// really up to you depending on your project)

- Serial.begin(115200);

+ Serial.begin(57600); // for Arduino Fio

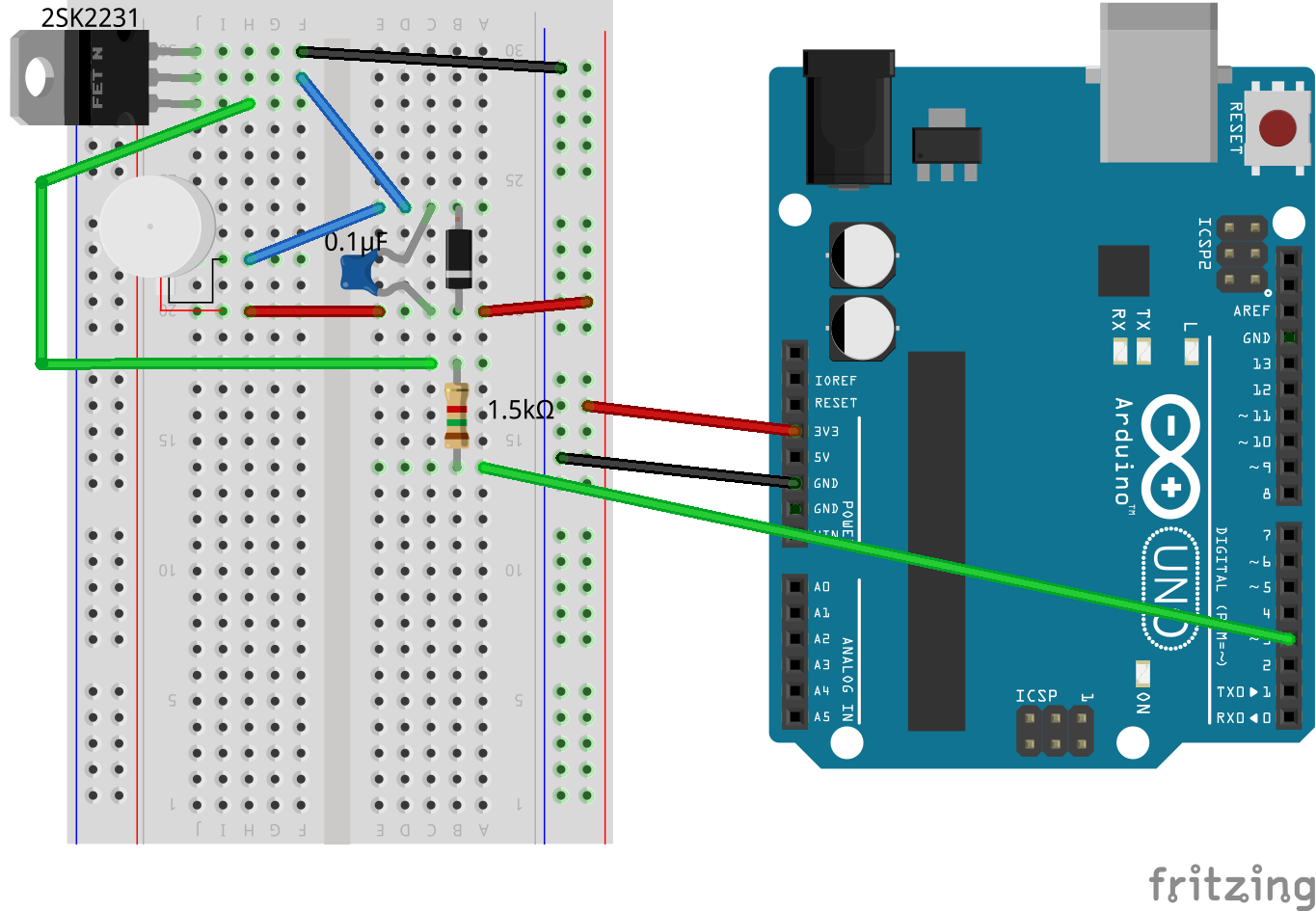

Step 6: realizing haptics with vibration motor.

Hardware

Software

W.I.P.

char c = Serial.read();

if (c != -1) {

c -= '0';

for (int i = 0; i < 5; i++) {

if ((c & 0b00010000) != 0) {

digitalWrite(3, HIGH);

}

if ((c & 0b00001000) != 0) {

digitalWrite(4, HIGH);

}

if ((c & 0b00000100) != 0) {

digitalWrite(5, HIGH);

}

delay(7);

digitalWrite(3, LOW);

digitalWrite(4, LOW);

digitalWrite(5, LOW);

if ((c & 0b00000010) != 0) {

digitalWrite(6, HIGH);

}

if ((c & 0b00000001) != 0) {

digitalWrite(7, HIGH);

}

delay(7);

digitalWrite(6, LOW);

digitalWrite(7, LOW);

}

}

Step 7: Integrating 5 and 6.

W.I.P.

Prototypes